Custom Packaging

FOAM IN PLACE

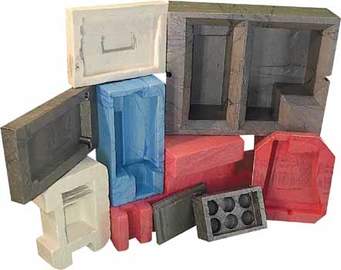

Foam in place packaging: Provides customized cushioning properties to ensure your product arrives at its destination in good order. We start by making a mold of your product that is used to create an “A” and “B” part that will fit perfectly around your product and keep it safe for shipping.

The insert is actually made from chemicals injected into a high-density polyethylene liner inside the mold. Once the chemicals are mixed together, they begin expanding to surround the shape in the mold creating your “A” and “B” clamshell style part. We then can make a custom box that will fit the molded foam to finish off the package.

Foam in place is an ideal material for shipping different configurations of fragile products or something that needs to stay cold. It will protect – sharp edges, corners, odd shapes, Metal, Plastic, Glass, and wood etc.

Foam in place packaging technology offers the highest degree of product protection available. It allows your product to arrive safely saving you countless hours and money in reshipping because of damaged goods. Foam in Place is effective in maximizing space and cost efficiency of your package, as well as increasing consumer confidence.

We also do Poly Foam that can be die cut into shapes and glued together as a kit. We make some pretty amazing things out of Poly Foam…we create lots of kits that can be used over and over to ship sensitive machined parts etc.